Micron Drymeister Flash Dryer. Changzhou Shinma Drying Engineering CoLTD a factory has 20 years of experience of professional and technical industrial servicelocates in Changzhou city of Jiangsu which is in the middle of Shanghai-Nanjing Express way.

Spin Flash Dryer Triveni Engineering Ahmedabad

In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

. The facility can handle various metals like Stainless Steel 304316 321 904L Duplex Steel Hastelloy Titanium and higher alloys. The simple spin flash dryer is designed to handle materials that can be suspended directly in air. Shachi has developed a highly optimised manufacturing facility for on-time delivery.

Table 1 summarizes the essential thermodynamic and transport properties of the air-water system. Our Spin Flash dryers are designed for continuous drying of cohesive and non-cohesive pastes and filter cakes as well as high-viscosity liquids. Up to 10 cash back The three-dimensional model of the spin flash dryer was drawn by SolidWorks software.

The basic dimensions of the simplified model are shown in Table 1 and the simplified model is shown in. 163 DESIGN OF FLASH DRYERS. Figure 164 presents a spin-flash dryer that can be.

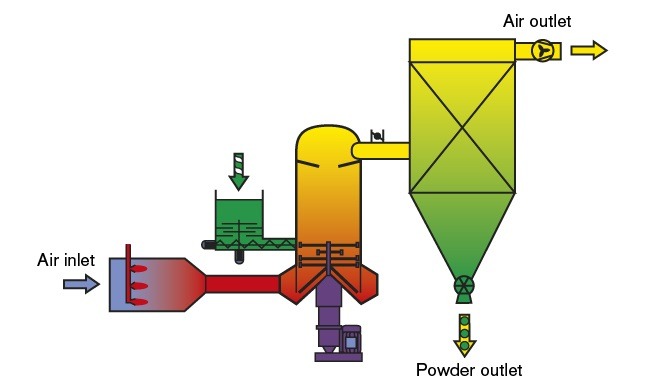

Hence it reduces overall plant operating cost. We need to analysis the internal flow field of the spin flash dryer. They are inherently cocurrent dryers with the hottest air contacting the wettest product.

As a designer we should know how to choose it the influence of operation parameters and the calculation. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products. To build plant system based on product peculiar characteristics.

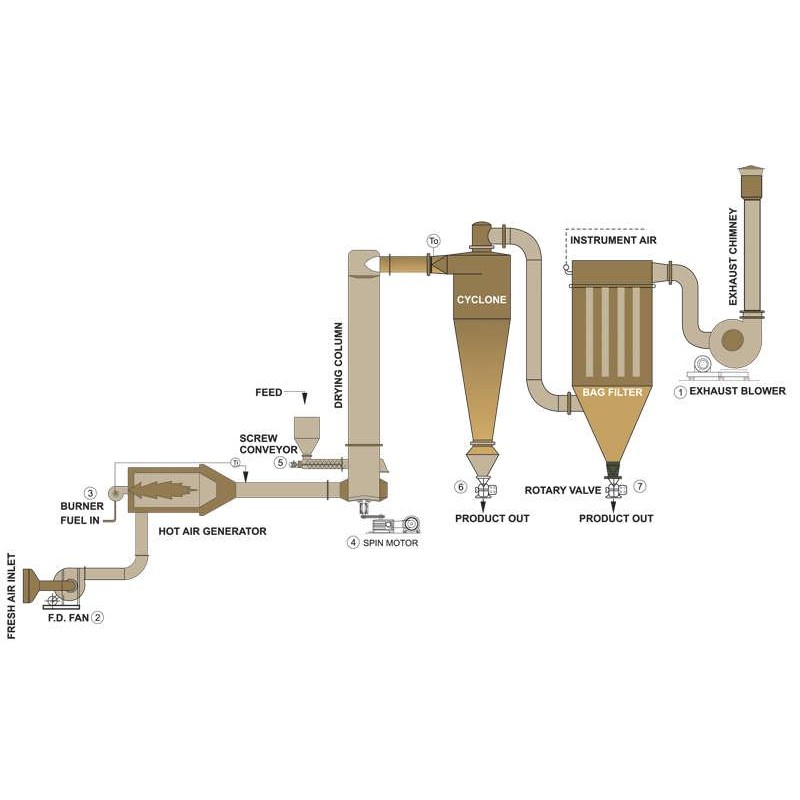

The main components in the Spin Flash plant are a feed system the patented drying chamber and a bag filter. Or FLASH Eav 150 Eav 750 - fair good fair continuous ROTARY 10 30 15 50 indirect Eav 20 Eav 33 - poor good fair continuous ROTARY 20 60 30 100 direct Eav 40 Eav 65 - fair fair good continuous SPIN FLASH 40 18 70 300 Eav 11 Eav 185 - good good fair continuous SPRAY 03 16 5 25. THERMAL SAND RECLAIMATION PLANT MANUFACTURERS Know More Leading Manufacturer Supplier of INDUSTRIAL FLUID DRYERS SPRAY DRYERS SPIN FLASH DRYERS ROTARY DRYERS Know More Leading Manufacturer Supplier of.

If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is. This article calculates the critical speed of the grading wheel rotor a small part of the SZ spin flash dryer based on finite element analysis software ANSYS. Flash drying is a continuous process with the dryer being either directly or indirectly fired.

To strive for excellence in all spheres of. Of the numerical calculations were partially compared. In a hierarchical system grading wheel plays a very important role in material scattering and classifying.

Design Of Centrifugal Spray Dryer. Rotary Dryer Calculation Volume calculation. The Drymeister is an economical alternative to spray dryers that can transform damp feed material into an ultra-fine powder with an extremely narrow particle size distribution.

It is generally manufactured by professional manufacturers. The drying process usually is completed in 0. Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

The Drymeister Flash Dryer combines drying milling and classifying in a single system with inlet gas temperatures up to 600C. Our company has 2 large modern construction machinery manufacturing plant equipped with whole line of sheet metal bending laser cutting. V15ms Dry Air Density.

Mechanical vapor recompression MVR technology in evaporator plant consumes less energy as compared to conventional evaporator. Horizontal Dryer 2 Parameter Unit Initial Net. Whenever possible to apply heat direct to the material to be dried Rotary Dryers of the Direct Heating Design are used.

On the basis of analyzing the line friction belt conveyor transmission mechanism of driving forces the calculation method of driving force as well as the design essentials of this conveyor system were pointed out. The Design of Spin Flash Dryer JIANG BinCHAI Ben-yinPENG Li-hua MIAO ShuaiDONG Xian-huaZHANG Lei Shandong Tianli Drying Equipment CoLtdJinan 250014China This paper introduces structure drying principles of Spin Flash Dryer and calculation and determination of related parameters. O o o o 0 o o o o o o o o o e o bro o o N o o o o o o o 0 bf O o o 0 o.

Rotary Dryer Kiln. So the external structure is ignored to construct a simplified physical model. High speed centrifugal rotary atomizer is the core part of Centrifugal Spray Dryer because of its high manufacturing accuracy and high speed.

In the conventional evaporator most of the energy in the form of steam generated is either lost or partially utilized. The tangential air distributor of special design introduces the air as an intense swirl flow. 60 kg of wet product contains 60 x 055 kg water 33 kg moisture and.

Vπr²L314x11²x2491m 3 82m 3 fulfill requirement Rotary Dryer Energy Balance. Dryers - Nutrition and Health Spin Flash Dryers. O o o o o o o o o o o o o o o o o o o o o o o o o o o O o o o o O E o o.

For evaporating moisture from concentrates or other products from plant operations Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption. The design calculations of such dryers. The wet material is metered into the drying chamber by a feeder pulverized and dried by stirring and vortex flow.

In Table 2 a listing of brief definitions of various terms encountered in drying and psychrometry is given. The clean thermal medium heated by the heat source enters the drying chamber in a tangential form forming a powerful vortex swirling airflow with the mechanical agitation mechanism. G 1 AV1000W1W2100W1 3AV100055-12100-55AV956.

According to the conditons that the line friction drive motor power the driving belt tensile strength and its minimum tension the calculation formula of transmission belt. Horizontal Dryer 1 Parameter Unit Initial Reduced Combustion Air Net Temperature 0C 88 88 O2 199 197 CO ppm 22 24 Combustion Efficiency 379 447 CO2 06 07 Flue Gas Temperature 0C 119 120 Ambient Temperature 0C 307 31 Excess Air 1990 1642 Pressure mbar 004 005 Table 6. 5 - 2 sees and the final moisture is generally in the constant rate drying zone.

The facility is well-equipped to manufacture test large-scale complex process plants for a variety of applications. In mechanical vapor recompression process entire. Mechanism prior to design work is strongly recommended.

Meanwhile in order to provide a theoretical evidence for the design of the grading wheels dynamic performance.

1 Simple Flash Drying System Download Scientific Diagram

4 Spin Flash Dryer From Devahastin S Ed Mujumdar S Practical Download Scientific Diagram

Xsg Series Spin Flash Dryer Changzhou Changhang Drying Equipment Co Ltd

Dryers Spin Flash Dryers Anhydro

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Request Pdf

0 comments

Post a Comment