This paper proposes the design of a coreless induction furnace to melt Aluminum which is represented by a transformer with N primary turns and one short circuited secondary turn. In theory the ore.

Pdf Modeling Of Electric Arc Furnaces Eaf With Electromagnetic Stirring Semantic Scholar

Making steel from ores.

. Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes. By Hartman Alan D. In Krugersdorp to a 12 MW DC arc furnace of ASEA design in 1984.

By the usage of this process we can get a pure form of steel from the scrap. The process of Electric Arc Furnace is better than the usage of the conventional process ie. Introduction Generally electric arc furnaces consume high levels of energy to run the steelmaking processes that uses the coal and the electricity.

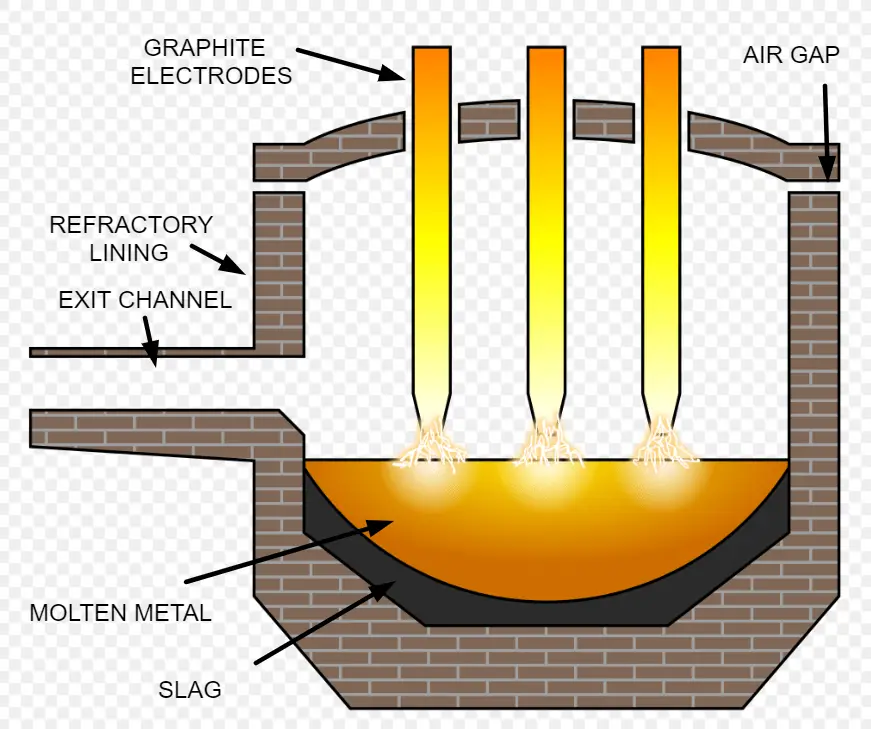

Cylindrical refractory-lined EAF are equipped with carbon electrodes to be raised or lowered through the furnace roof. PDF - 73793 KB File Type. 2 Introduction to Electric Arc Furnace Steelmaking 21 Basic Concepts The Electric Arc Furnace EAF is today the most common way to recycle steel from scrap.

Large number of electric reduction furnaces and published the result of his work on several occasions during the 1970s Westly 1974 1975 1979. Results showed that CFD simulation could efficiently be used to develop and investigate EAF in design phase. Chromite Smelting Mintek 4 began investigating alternative smelting methods for ferro-alloy production in the mid to late 1970s.

This work has three main contributions. These references are highly. Electric arc furnace has developed significantly over the past 30 years.

There is a broad variety of steel scrap both in terms of composition from plain carbon steel through to highly alloyed tool steel and geometry from finely shredded sheet through to. 32 Furnace design 18 321 Ultra High Power transformer 18 322 High-impedance system 19 323 Aluminium electrode arm 21. Shows that it employs electric arc furnaces of varying capacities vintages and energy performance.

The aim of this research is to develop a dynamic model of an industrial EAF process and investigate its application for optimal EAF operation. However further improvements in productivity and energy efficiency are required. There are two major reasons for this trend-lower.

Developments in EAF performances 3. 17th IEEE International Multi Topic Conference 2014. Math-ematically the electric arc can be described as an impedance load whose resistance Ra can be mod-eled by means of the well-known Cassie-Mayr model 1 2 3 from Eq.

Advantages of Electric Arc Furnace. The growing ferro-alloy industry in South Africa faced the problem of. Today electrode and electric power consumption and tap to tap times are reduced considerably as shown in Figure 1-1 1 2 3.

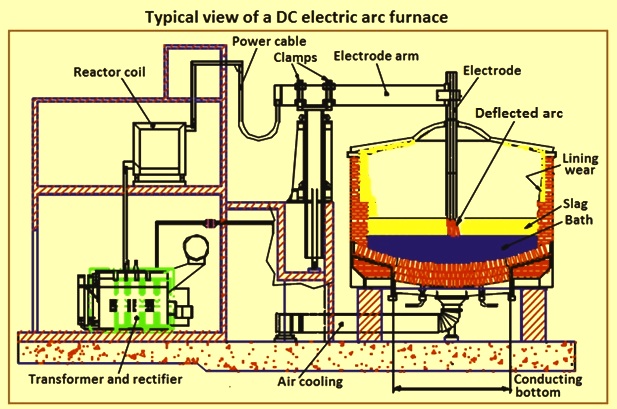

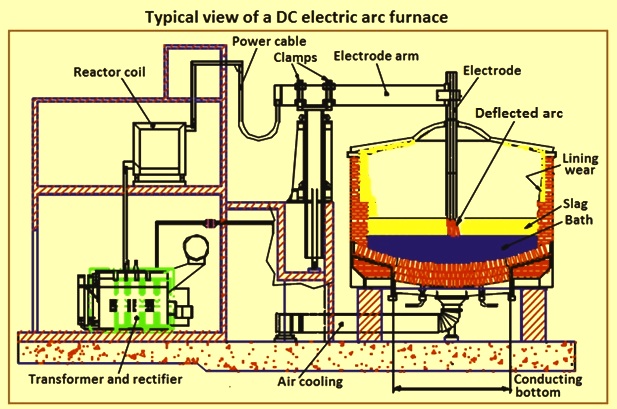

2 Physical Model of Arc Furnace Figure 1 shows the physical model of the electric arc furnace. The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations. An electric arc furnace was designed and constructed to melt approximately 5kg of steelcast iron scraps using locally produced Soderberg electrodes.

First-generation furnaces had a capacity in between 1 and 15 t. - The allowance for the design duty shall be regarded as a consideration for the fouling of the heat exchanger train and the furnace inlet temperature shall be lowered in proportion to the design duty allowance. These improvements to the processing of scrap steel comprised of larger more efficient and higher capacity furnaces.

Kawałkowski 1 ABSTRACT This article includes basic information about the functioning of electric arc furnace EAF and a modern research method - Computational Fluid Dynamics CFD - used among other things in metallurgy. In order to change the input active power of the EAF transformer TF MVLV is used. The Model of Power System with Ac Electric Arc Furnace The electric diagram of a source supplying an EAF is illustrated in Figure 1.

Each of these electrodes has a diameter of roughly 15m weighs approximately 40 tons and is 1 to 2 stories tall. The paper also contains a. In this particular EAF model there are three electrodes that are moved vertically up and down with hydraulic actuators.

The rst contribution is developing. The energy intensive nature of electric arc furnace EAF steelmaking necessitates that efforts to reduce greenhouse gas GHG emissions will affect steelmakers directly andor through electric. This great variety of our designs is described below.

An electric arc furnace EAF is a metallurgical furnace used to produce carbon and alloy steels. EAF Furnace Design 1 Hydraulic tilting platform. Design of an experimental electric arc furnace 1992.

DisAdvantages of Electric Arc Furnace. 1 Electric steelmaking The electric arc furnace applied in steelmaking was invented in 1889 by Paul Héroult. - If the case regarded as the highest duty is an extremely rare operation the design duty may be 100 of the furnace duty in the.

Tests carried out showed that it. Many fur-naces many features. The Second World War saw a steep increase in the use of these furnaces leading to the modern Electric Arc Furnace design operation and working principles.

The input material to an EAF is typically almost 100 percent scrap steel. With this background the United Nations Development Programme UNDP had entrusted The Energy and Resources. Pyrometallurgy DC arc furnace electric arc smelting Abstract.

Water-cooled panels furnace roof off-gas elbow post-combustion chamber4 Power supply gantry system with roof lifting and swing mechanism electrode supporting arms water-cooled electrodes. The electrical model of the EAF can be described as a non-linear 3-phase electric circuit whose main non-linearities are represented by the electric arcs. Eccentric Bottom Tapping EBT tap-hole refractory lining.

PDF - 73793 KB Laser tracking and tram control of a. The electric arc furnace EAF is a highly energy intensive process used to convert scrap metal into molten steel. Emerging new technology started in the beginning of the twentieth centu-ry when wide-ranging generation of relatively cheap electric energy started at that time.

Instabilities in electric steelmaking furnace arcs cause electrical and acoustical noise reduce operating efficiency increase refractory erosion and increase electrode usage. The use of electric arc furnaces EAFs for the production of steel has grown dramatically in the United States. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes.

Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. SMS SIEMAG Submerged-Arc Furnaces and Electric Smelters 8 A WIDE RANGE OF DESIGN SERVICES We have designed a large variety of sub-merged-arc furnaces and electric smelters adapted to suit the individual requirements of the customer. A 100T furnace would process the scrap in about an hour using a transformer of 60MVA.

THE ELECTRIC ARC FURNACE OFF-GASSES MODELING USING CFD M. In this figure bus 1 is the point of common coupling PCC which is the supplying bus of the EAF transformer. In 1975 EAFs accounted for 20 of the steel produced.

ELECTRIC ARC FURNACE CFD COMBUSTION RADIATION HEAT TRANSFER. By 1996 the figure had risen to 39 and by the year 2000 or shortly thereafter could approach 50. The advantages of Electric Arc Furnace are as follows.

Design Features Of An Ac Electric Arc Furnace Ispatguru

Electric Arc Furnace Definition Types Construction Working Application Advantages And Disadvantages Pdf Notes

Design And Prototype Development Of A Mini Electric Arc Furnace Semantic Scholar

Electric Arc Furnace Electrical4u

Dc Electric Arc Furnace Ispatguru

Electric Arc Furnace Design Operation And Working Principle Bright Hub Engineering

Pdf Modelling And Control Of A Three Phase Electric Arc Furnace Semantic Scholar

Electric Arc Furnace Industrial Efficiency Technology Measures

0 comments

Post a Comment